Takt Time

Takt Time -

Takt is a German word meaning ‘beat’ or drumbeat (metronome)

This means matching the pace of production to customer demand.

Adherence to Takt will ensure customer satisfaction through 100% on-time delivery. This will also ensure not too many or too few are delivered when the customer does not want them. If the customer wants 200 items per week, then we need to deliver 200 items per week and not 800 items at the end of the month. The customer may have staff waiting around for 4 weeks if we do it this way.

Benefits

• Links production activity to actual customer demand

• The ‘Drumbeat’ of Production enabling better planning and forecasting

• Ensures all production activity will be synchronised from 1st process to final assembly process. - ‘Flow’

• Definitions

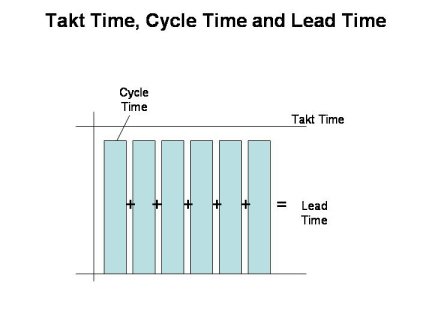

Takt = The pace at which the customer requires products.

Cycle Time = The time at which a process cycles to produce products.

Lead Time = The total production time from start to finish, including inventory time between processes.

Don’t get them confused!!

Calculating the ' Takt Time ' Drumbeat

• How to calculate Takt time

this relates the customer demand to the time available.

Takt = Production Time Available / Customer Demand

Time is deducted for: Lunch and tea breaks Team briefing times TPM breaks Clean down time

Get Lean Six Sigma Training which includes Takt Time

One of the fundamentals upon which the Toyota Production System was built

In order to more fully understand the principles described here, we would recommend signing up for the lean six sigma course described above.

Alternatively, if you really wish to progress in your career, you may want to consider signing up for the full black belt certification course below.

Becoming certified will greatly increase your chances of promotion, progression, a bigger salary or a greatly enhanced day rate if you are in the contract world of consulting.