Kanban System, Is It The Answer?

Building the foundation for a successful Lean Six Sigma Implementation

Five years ago, a client asked me when they could start putting in place a Kanban System in their organisation following the completion of a ‘Diagnostic’ activity. This client had heard about Kanban systems and wanted to implement them across his organisation, thinking it would solve all his operational issues

I told the Head of this organisation that they weren’t ready for any Lean Six Sigma tools, let alone implementing kanban systems across the board and his jaw almost hit the floor! I qualified my point by asking him some very basic questions, things like; How many do you need to complete today? How many people will you need to complete today’s requirement? How big is your performance spread? What does a good day look like? Along with a few more simple but essential questions that you would expect any good Operations person to have a good handle on.

Sign up for our weekly newsletter for updates, articles and free giveaways of case studies, templates and training materials every issue! Simply enter your e-mail on the right

Kanban System - Planting a flower in the desert!

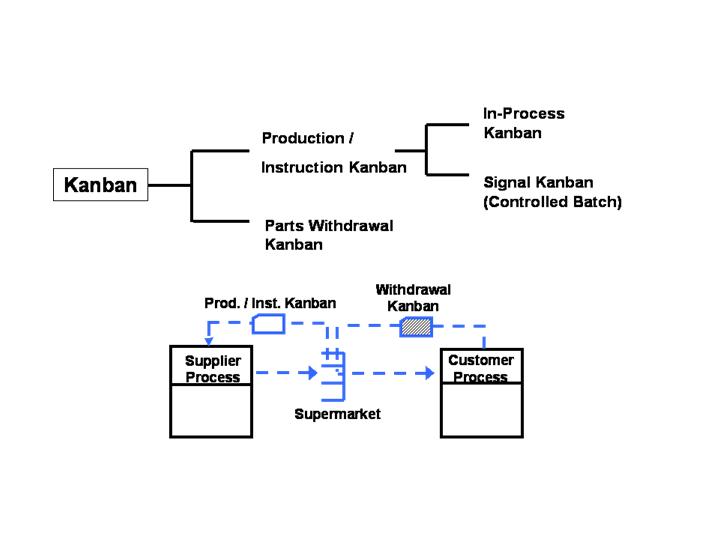

Kanban System

Kanban SystemHe couldn’t answer a single question and quickly understood what I was getting at. We needed to get the foundations in place FIRST, before we could begin a typical Lean Six Sigma intervention, let alone start putting random Kanban systems in place. We needed to get his operation ‘In Control’, so that he could at least answer some of the questions asked of him. The phase I was moving him into was the ‘Stability’ phase, which would then give us a stable platform from which to build. Putting a kanban system in place while the operation was in it's current position would be like planting a flower in the desert - it would have looked nice for a very short while but would quickly die and be completely unsustainable because the environment isn't conducive with sustaining it.

The primary purpose of the ‘Stability’ phase is to lay a solid foundation for the organisation. At the conclusion of this phase you should have a certainty that the ‘Ship has been steadied’, Fire fighting is a thing of the past and ‘Forward’ is the only way to go.

Depending upon the outcome of the Diagnostic Phase some actions may be required immediately to prevent disaster. This is where the Stability phase and the Strategy phase often overlap.

There is no ‘Right’ or ‘Wrong’ order to carry out the following actions, it will be solely dependent on what you uncover in the Diagnostic Phase.

For example, if a major cause of your companies problems was down to poor deliveries due to lack of visibility of shop floor productivity levels, meaning you never know when your product is coming off the line. You immediately put in place measures or KPI’s (Key Performance Indicators) to address this and give you that visibility.

This can be done very quickly while other things are being worked on – Put your customer protection in place IMMEDIATELY, this will give you some time to work on the long term countermeasure.

Implement Standardised Operating Procedures

“Without Standardisation there can be no improvement” (Taichi Ohno). Implement Standard work in the operation and ensure adherence to this relentlessly. Once this is in place and adhered to, if an error occurs there can be only one of two possibilities; either the process wasn’t followed, or the process is wrong. It really is that simple (Taking breakdowns and catastrophic failures out of the equation)

Institutionalise daily comms / Operations meetings to convey to all staff that what they do is important and to allow them to understand what is required, by when and to what standard.

Getting these seemingly simple things in place and rigidly adhered to will give you benefits beyond your imagination, as well as starting to create the culture which will then pave the way for future changes and improvements to be implemented much more smoothly.

There is one caveat: Involve the people every step of the way. If the people are involved and on board everything else is easy!