Poka Yoke or Error Proofing

Poka Yoke / Pokayoke / Error Proofing What It Is

Poke Yoke or mistake proofing means taking steps to ensure errors or abnormalities can't occur.

It can involve using checklists, quality checks, part or tool design, machine modification, setting tolerance limits and so forth.

There are three types of Pokayoke:

1 - Contact type:

The use of shape, dimensions or other physical properties to detect the contact or non-contact of a particular feature.

E.g. Things only fitting one way

2 - Constant number type:

If a fixed number of actions or movements are not made an error sign is triggered.

eg: completing data entry fields when taking an order

3 – Performance sequence type ensures steps are performed In the right order

eg, the use of a checklist for pre-flight checks or completing forms In a logical way.

Poka yokes are either:

. Shut out type

- so preventing an error being made.

. Attention type

- highlighting that an error has been made.

'Shut-out' is clearly preferable to 'Attention' as it prevents waste and doesn't rely on the error signal being noticed.

The ideal PokaYokes are:

· inexpensive

· simple and easy to implement

· specific to the need

· developed by every employee

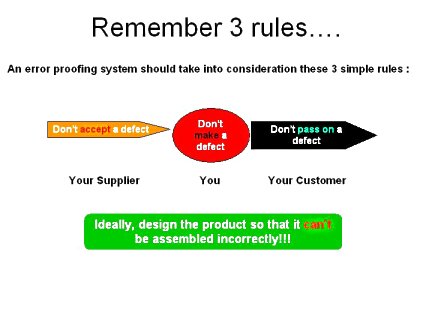

The three golden rules of Poka Yoke

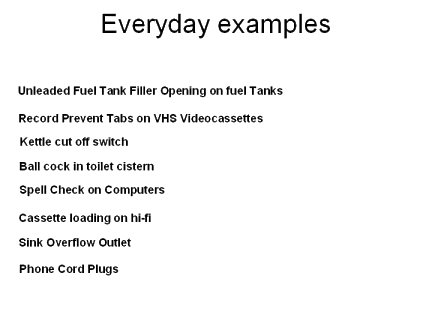

Everyday examples of Poka Yoke:

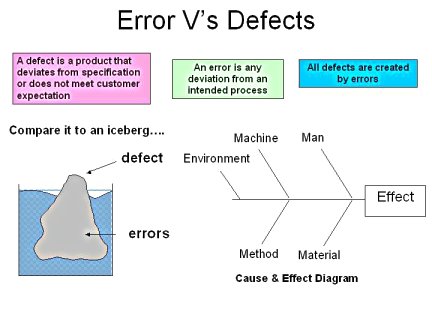

To enhance the understanding of Pokayoke / Error Proofing, it is important to understand the difference between a defect and an error We can use the cause and effect diagram to identify the the errors that cause defects to occur.

An error is any deviation from a specified manufacturing process.

Errors can be made by machines or people and can be caused by errors that occurred previously.

All defects are created by errors.

This means that if errors can be prevented, no defects will be created.

By using Error Proofing, the errors that cause defects are located and eliminated.

Error Proofing should be continuously used to locate and prevent new errors.

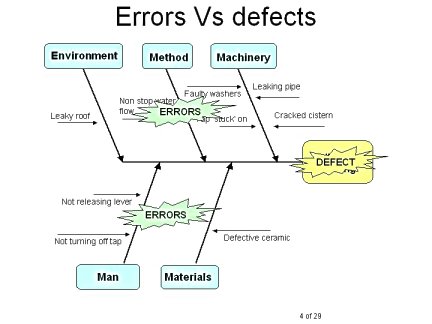

Here is an example of a completed cause and effect diagram, once the possible causes (errors) are identified, the most likely errors can be counter measured through various Poka Yoke techniques.

Poka Yoke

Error proofing can only affect the errors which potentially cause defects – not all errors cause defects!

Here is a list of the 10 most common errors which EP is designed to correct or eliminate:

1.Processing omissions: Leaving out one or more process steps.

2. Processing errors: Process operation not performed according to the standard work procedures.

3. Error in setting up the workpiece: Using the wrong tooling or setting machine adjustments in correctly for the current product.

4. Missing parts: Not all parts included in the assembly, welding, or other processes.

5. Improper part/ item: Wrong part installed in assembly.

6. Processing wrong workpiece: Wrong part machined.

7. Operations errors: Carrying out an operation incorrectly; having the incorrect revision of a standard process or specification sheet.

8. Adjustment, measurement, dimension errors: Errors in machine adjustments, testing measurements or dimensions of a part coming in from a supplier.

9. Errors in equipment maintenance or repair: Defects caused by incorrect repairs or component replacement.

10. Error in preparation of blades, jigs, or tools: Damaged blades, poorly designed jigs, or wrong tools.

How to use Poka Yoke

1. Identify the operation or process that needs to be mistake proofed (target areas where there are high numbers of errors or where even single errors are very costly).

2. Use the 5 Whys or cause and effect analysis to get to the root of the problem.

3. Decide whether to use a shut-out or attention type method (there may be technical or financial reasons why you have to go for the latter) to tackle the problem.

4. Decide whether a contact, constant number or sequence method is best (this will hinge on the nature and purpose of the activities).

5. Design an appropriate poka yoke.

6. Test it to see if it works (try to avoid large expense before you have completed this step - use mock ups or make-do's).

7. Once you have a working method then ensure you have the right tools/checklists/software, etc for it to work consistently and correctly.

8. Train everyone to use it.

9. After it has been in operation for a while (the time period will depend on the frequency of the activity) review performance to ensure errors have been eliminated.

Take whatever steps are needed to improve on what you have done.

How it helps

· By taking steps to make it impossible to make mistakes, waste is prevented and processes run more smoothly.

· Enforces operational procedures or sequences

. Ensures quality at the source instead of quality after the fact.

· Eliminates choices leading to incorrect actions

Don't worry about getting it right - Just get it going, Poka Yoke