Lean Six Sigma Yellow Belt Training and Certification

Sign up for our weekly newsletter for updates, articles and free giveaways of case studies, templates and training materials every issue! Simply enter your e-mail on the right

Getting certified as a Lean Six Sigma Yellow Belt is your first step on your journey to becoming an expert in problem solving, business improvements and giving you greater marketability and earnings potential.

Before you decide whether you want to become certified, simply watch the videos below to determine whether this is for you.

You may simply want to get a better understanding of the subject and if so, the videos below will be perfect for you.

Lean Six Sigma Yellow Belt - Course Outline

INTRODUCTION & AGENDA

Lean Sigma Awareness – Yellow Belt Training

Standard Business Roadmap – Steps to follow in ANY Improvement activity

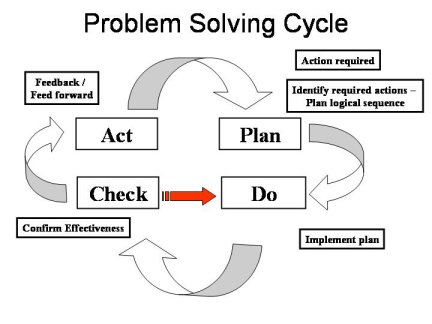

Basic Problem Solving

Lean Six Sigma Yellow Belt Overview

Lean works in any repeatable process, it is a fundamentally different way of managing and developing processes

Originally Based upon Japanese manufacturing methodologies

= Doing the most with the least, consistently to a set quality level

World Leader in Lean seen to be Toyota

What Lean is NOT -

Getting colleagues to work faster and faster

Blindly implementing a set of improvement tools

Only of value in high volume processes

Having a ‘tidy-up’

Incompatible with other improvement methodologies (e.g. Six Sigma).

What is Six Sigma?

6 Sigma manufacturing philosophy came from Motorola

They recognised that sufficient process improvement would not occur using a conventional approach to quality. It was developed to help them reduce variation within a process by focusing effort on improving inputs to a process rather than reacting to outputs. (Standardised Inputs = Standardised Outputs)

The process was failing the customer expectations

Traditionally, processes aimed for process capability of 3 to 4 sigma (93% to 99.3% acceptable)

The customer received 6200 defective product per million at best

Processes now aim for 6 sigma

The customer would receive 3.4 defective products per million