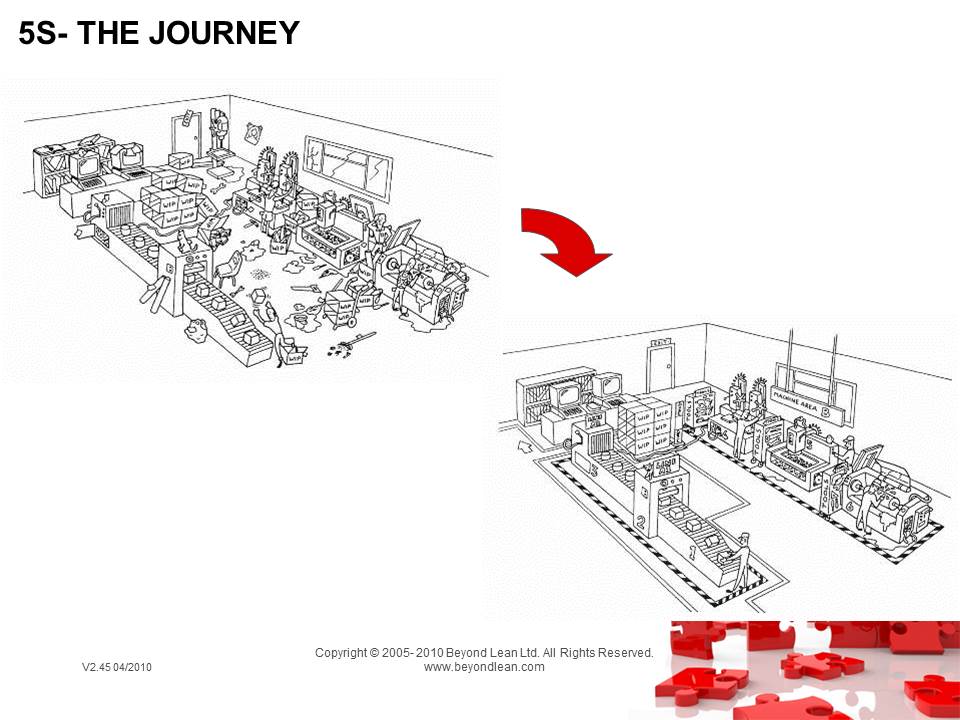

Lean 5S - The Foundation of your business

Sign up for our weekly newsletter for updates, articles and free giveaways of case studies, templates and training materials every issue! Simply enter your e-mail on the right

Elements and the objectives of Lean 5S

Benefits of Workplace organisation

Description the steps of application

Summary

Objectives

Stages

SORT

•Eliminate all non-essential tools, materials from the workplace

STRAIGHTEN

•Organize all necessary tools, materials

•Assign an optimal area in the workplace

SHINE

•Regularly clean the workplace and equipment

•Pre curser to TPM

•Exposes potential hazards (early warning system)

STANDARDISE

•Develop standard procedures and checklists to maintain an orderly, clean, and functional work area

SUSTAIN

•Implement systems to monitor and maintain to ensure the workplace is improved and this becomes part of the culture

•The implementation of the Lean 5S program in a workplace involves not only an initial improvement of a given area, but, more importantly, it involves the creation of a disciplined system to maintain the improved condition over time

– Creates a foundation to build stability

– Key for building a successful continuous improvement environment

EFFECTS

•Improves incidental activities by decreasing operator movements through improved layout of tools/equipment

•Eliminates non-value-added activities (e.g., searching for tools) by clearly identifying useful materials and then organizing those items and positioning them in their optimum locations

Lean 5S – Workplace organisation benefits

Cultural

•Creates an awareness of the principles

•Develops an understanding in the

organisation of

the connection between workplace organisation and workplace efficiency

•Completely cleans and organizes a "model area" as the start of ongoing improvement activities

•Develops standard procedures for maintenance and a system to enforce them

•Improves morale and increases worker involvement levels

Operational

•Reduces cost

•Improves operating conditions

•Reduces equipment operational errors

•Improves process reliability

•Promotes safety

•Increases equipment availability

•Improves customer perception

Lean 5S & Continuous Improvement

•Increased safety

•Improved work environment

•Greater visibility

•Higher performance

STEP 1 – Sort

•Determine what is necessary

in the workplace, remove

other items

•Determine storage location based on frequency of use

•Use only 1 organisation method within the company to create immediate visibility and response (i.e., tagging method)

–-If there is a question, use a red tag which requires further review

•When in doubt, throw it out!

•Organize only what is needed, in the amount needed, when it is needed

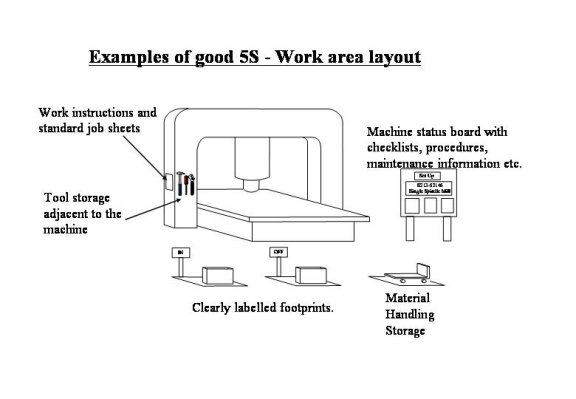

STEP 2 Set In Order

•Plan an optimum layout

•Reconfigure the area to match the planned layout

•Use floor tape to mark the new locations for all equipment, racks, production materials, etc., as well as aisles

•Determine the best location for tools, gauges, work aids, and other small items

•Mark and label all locations

•Build or install racks for frequently used items

•Store items close to their points of use

•A place for everything and everything in its place

•Visual controls communicate information about the work area

•Eliminates Searching

STEP 3 - Shine

•Clean the entire work area including floors, walls, equipment, etc.

•Tag any leaks, broken dust guards, etc. Make sure that anything that has been tagged is repaired as soon as possible

•Restore the equipment to its original functional condition

•Paint or refinish areas

•Assure that the proper cleaning tools are present to maintain the improved condition

•Assure that proper collection methods exist for normal work debris and trash

•Maintaining everything in top condition enables it to be used at any time

•Clean work environments relieve frustration and stress

•Daily cleaning should be a part of the normal work routine

•Relieves stress and strain – when something needs to be used, it is in good working order

•Increases work efficiencies

STEP 4 – Standardise

•Establish a standardized approach

•Define what needs to be done on a regular basis to maintain the work area

•Determine the intended frequency – classify as daily, weekly, monthly, and semi annually (other time increments may be used)

•Use this information to write standardized 5S checklists

•Decide who should be responsible

•Incorporate the content of the checklists into standard work instructions

•Ensure that the first 3 steps

are maintained

•Create and develop organisation

•Develop 5S discipline

•Provide a baseline for improvement

STEP 5 – Sustain

Develop a 5S audit sheet as a guideline

•Establish an audit schedule

•Perform regular Lean 5S audits

•Divide the plant into different areas and assign 5S responsibility

•Involve operators, supervisors and managers in Lean 5S audits on a regular basis (possibly monthly)