Business Strategy

Sign up for our weekly newsletter for updates, articles and free giveaways of case studies, templates and training materials every issue! Simply enter your e-mail on the right

The first step of producing your business strategy is to lay down a clear business purpose which can be communicated to the whole workforce.

A series of visionary, yet specific, purpose statements can help guide all employees during any type of change process.

The development of a business purpose statement is critical to providing human energy and vitality to the whole change program.

Everyone needs a purpose to believe in

This single or series of purpose statements could also be used to define clear operating principles, should you enter into a "Gateway" or "Partnership" process with the workforce and / or unions.

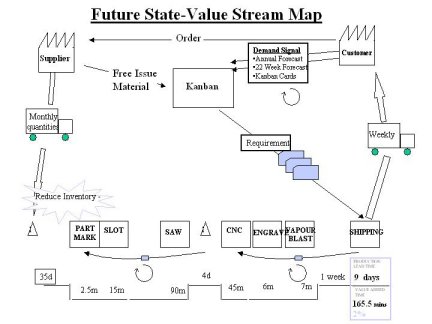

Future State Value Stream Map

This will provide the visual vision for the future, showing exactly how material and information will flow through your organization.

Business Strategy Planning

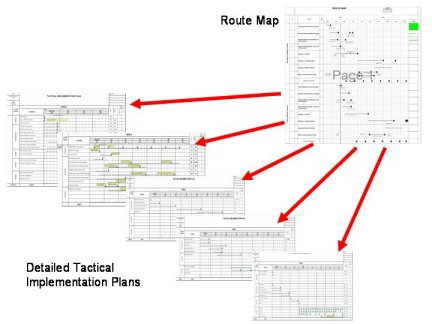

Route Map & Tactical Plans

These are your working tools, the detailed plans that will turn the Future State Map into a reality

The team can then begin to detail the tactical implementation plan to achieve the future state. Using the sizeable portions from the material and information flow diagram, the project team should focus on each portion progressively, starting at the point closest to the customer and working upstream. Specific objectives and goals for each portion of the plan along with an associated timing and resource requirements must be given. Key milestones that fall on the critical path of the implementation plan should be highlighted.

When creating the improvement plan, the project team should not be distracted by the opportunities of quick or hoc savings. The implementation plan should follow the stated structured approach of working backwards from The customer. The team must only apply Lean Six Sigma tools or techniques in the pursuit of improved flow. This will be explained in greater depth in section

Budget requirements should be considered on a project-by-project basis. Most improvements in Lean Six Sigma should be taken with a low cost/no cost approach, allowing maximum financial impact. Only justifiable cost should be incurred in the budget plans.