Your Headquarters for Lean Six Sigma & Operational Excellence Deployment, Coaching and Skills Transfer

What can Lean Six Sigma do for you and your business?

Every business is set up perfectly - to deliver exactly the results it currently gets. The successful ones go from strength to strength while others seemingly lurch from crisis to crisis. Yet how is it that two equally capable competitors see one of them grow and one of them fail?

The difference, for a majority of the truly successful ones, is a proficiency in, and a strict adherence to the core principles of Lean Six Sigma. No "magic tricks" or "getting lucky" involved.

Is your business, department or division currently struggling in the areas of efficiency, quality, on time delivery to customers and rising costs? Then you are not alone but simply in the same boat as 99% of all other businesses.

That's the bad news.

The good news is that we're here to help you improve, so that you and your enterprise can become more successful in becoming more efficient, more cost-effective, while consistently delivering high quality products and services to a loyal and growing customer base.

|

And even more good news. It doesn't have to be painful, disruptive, or expensive.

Over the Past 19 years, we have worked with a wide array of companies in several different sectors, saving them in excess of £40 million in documented benefits, as well as improvements to delivery lead times, reduction in risk exposure and quality improvements.

Let us help you effect the kinds of growth, savings and efficiencies that up until now seemed unreachable at any cost.

Why Lean Six Sigma Training & Certification?

We are currently running a limited-time-only marketing test and are giving you a massive 90% discount on all our Lean Six Sigma Certification courses. Act now and take advantage!

The risk of global recession is set to be with us for the next few years and one sector, more than any other is set to be in great demand – Business Improvement Professionals.

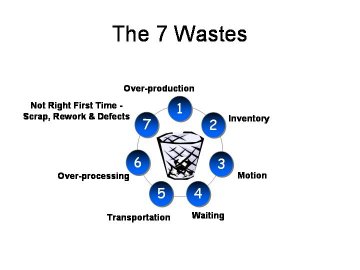

Businesses must remove excess costs from their operations to remain viable. They need to increase profitability and productivity, remove waste and variation from their processes in order to stay in business and remain competitive.

How will they do this? By employing Lean and Six Sigma (Lean Six Sigma Training & Lean Certification Online) methodologies as part of their business as usual.

These skills are in great demand and there are a lot of experienced Lean Six Sigma professionals out there. The only way to ensure you get to the front of the queue and to the top of the earnings ladder is to become a Certified Lean Six Sigma Black Belt.

Our online Green Belt and Black Belt students deliver an average of £50,000+ in tangible benefits as a result of completing the course.

Lean Six Sigma Business Diagnostic

Are you are a small company with a limited budget looking for information or advice, or maybe wanting to get hold of some basic training material to roll out yourself in areas you have identified as needing some attention ? Whatever your needs, we will be able to help. Even if it's just some advice you need!

Have a look at our latest service offering - The 'Business Operations Diagnostic'. This is perfect if you have a limited budget. This service really does put the 'Big 4' Consultancy advice within reach of ALL businesses. Including yours!

Our mission is a simple one. We aim to provide YOU with the tools and knowledge to change YOUR business........In short we'll help you to help yourself.

We have developed a system that will work for any business. Yours especially.

A full breakdown of this is contained in our Lean Six Sigma Black Belt Training & Certification course, details of which are available at Online Black Belt Training & Certification